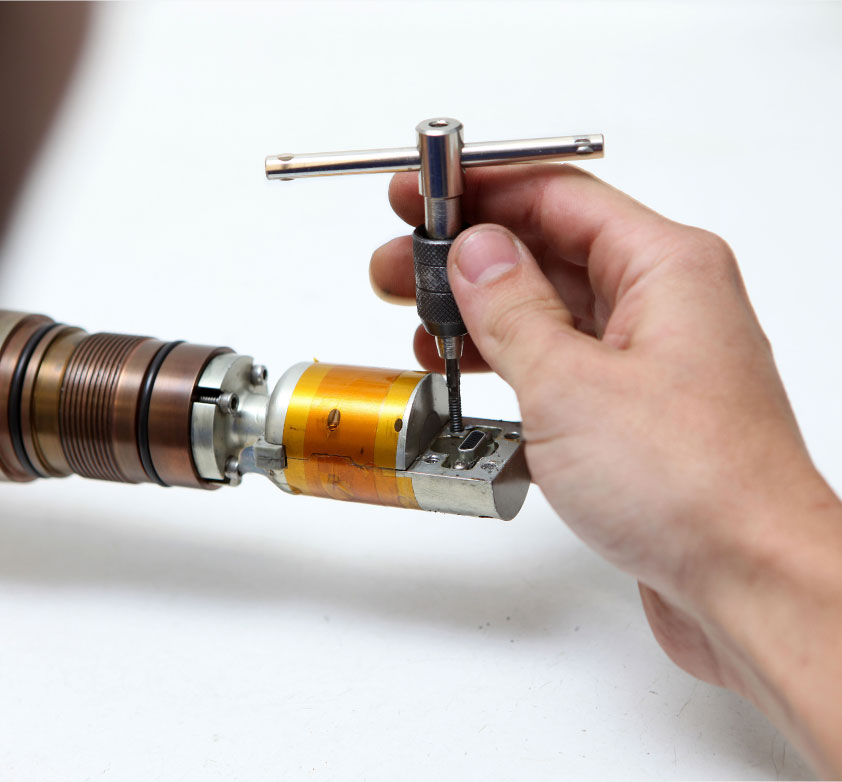

In house Parametric Modeling and Rapid Prototyping capabilities allow our team to quickly develop concepts into reality.

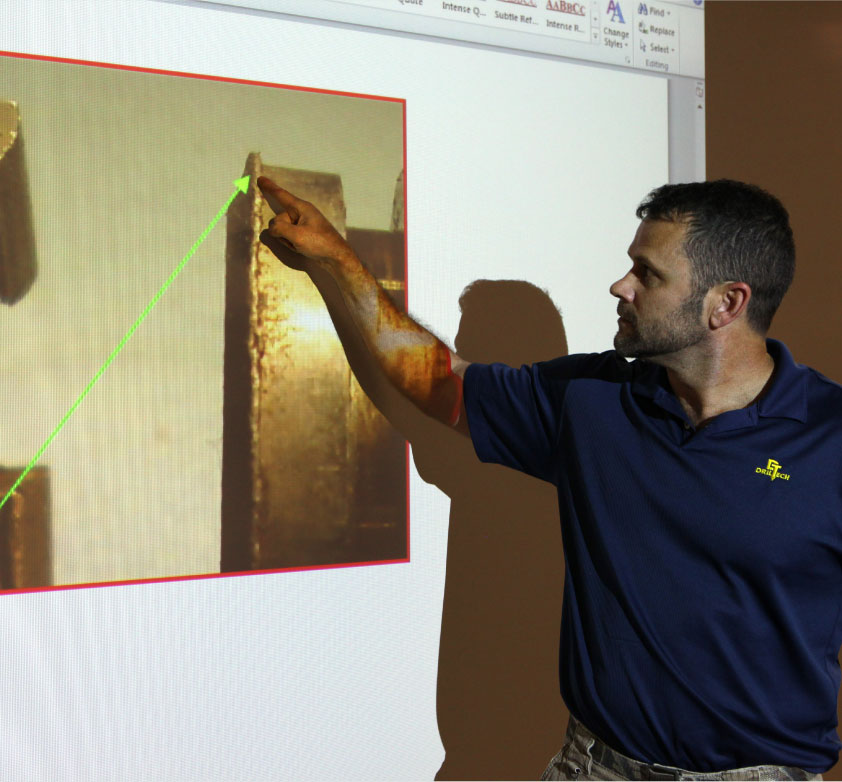

Our Lead Operators have over 20 years of experience in the industry.

We build personal relationships with drilling engineers, geologists, and rig personnel and provide 24/7 support to answer questions, immediately implement specific needs or wants (real-time inclination, shock and vibe data, changes to gamma logs, etc), and to also offer recommendations based on experience to aid in the success of each well drilled.

We also provide 24/7 On-Call support for our field operators to help them give you the best possible service including: Logistics Support, Pre-job & pre-run setup, Troubleshooting assistance and Remote Access Capabilities.

We adjust our configurations prior to every run based on client needs and wants. The following are just a few of the things we do to optimize your run.

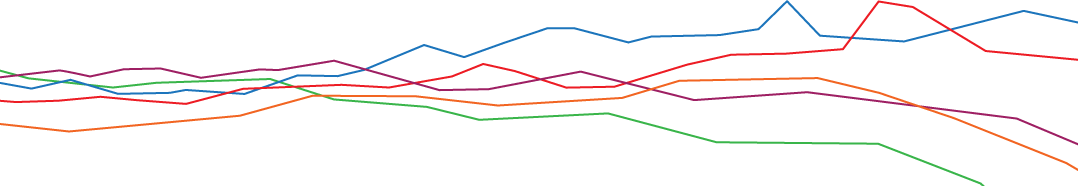

This process spreadsheet is basically a one-stop-shop for field operators to set up MWD configurations for each specific run. Once drilling parameters, BHA component details, and mud properties are determined for the run, the field operator simply inputs this data into the PRDS to determine the many variables that will result in his planned configuration, including:

The PRDS will automatically flag any parameter or setting that is not within accepted ranges with RED or YELLOW, notifying the field operator that changes to set up may be needed in order to ensure a problem-free run.

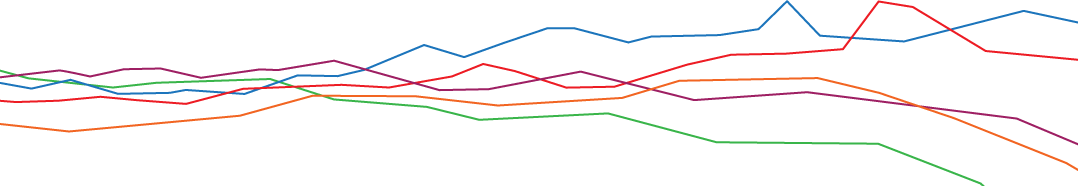

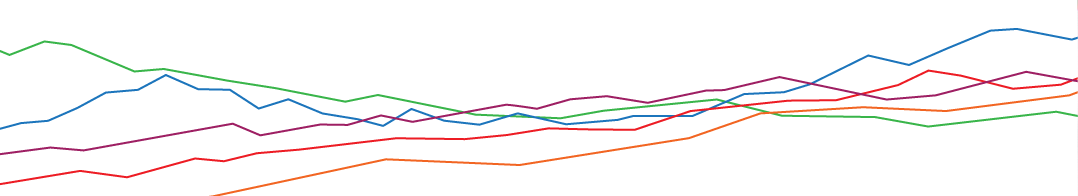

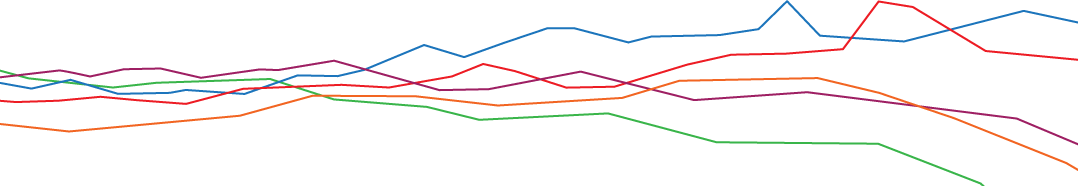

Field Data Quality Review (FDQR) are conducted per well per day. Process includes:

FPR’s (Field Process Reviews):

keeps availability of support at optimal levels for our customers and operators.

Are constantly being updated as new conditions, lessons learned, updated technology, and new tools / advanced variables dictate

No matter the time of day or night,

we are there for our customers.